As the business landscape changes and increases in its versatility, operations, optimizing efficiency, managing resources, and ensuring a seamless workflow are paramount for success. Chief Operating Officers (COOs) and executives overseeing operations face a myriad of challenges.

Resultingly, it requires a comprehensive approach to navigate the complexities of today’s industrial environment. One key discipline that plays a crucial role in enhancing operations is Industrial Engineering.

In this article, we will take a closer look at the role of industrial engineering in operations and what COOs can do to improve the symbiotic relationship between the two elements.

Understanding the Distinction

While the two concepts are often mistakenly used interchangeably, it is important to note that they both play a completely different yet symbiotic role for COOs looking to improve their organization.

Industrial Engineering

At its core, industrial engineering is a service to management, rooted in engineering principles. Its primary focus lies in enhancing productivity within the engineering organization, departments, and specific tasks.

F.W. Taylor, a pioneer in both operations management and industrial engineering, emphasized the need for individuals with executive ability, practical familiarity with engineering processes, and a keen awareness of economic factors.

Operations Management

This branch of management is dedicated to the planning and control of an organization’s operations. Initially introduced as shop management by F.W. Taylor, operations management has evolved into a comprehensive discipline encompassing production, logistics, and supply chain management.

The essence of operations management lies in effective planning, organizing, resourcing, direction, and control to accomplish tasks and ensure the growth and survival of an organization.

Navigating the Landscape

The relationship between Industrial Engineering and Operations Management becomes clearer when considering their historical development. While operations management, initially termed shop management, focused on the efficient management of factories and related activities, industrial engineering emerged with a concentrated effort on productivity improvement.

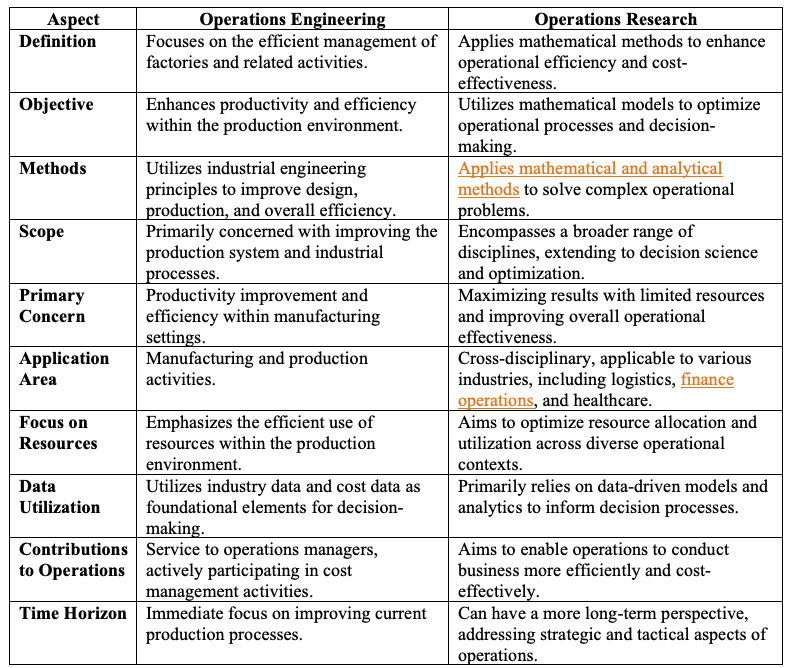

Operations Engineering vs. Operations Research

It’s crucial to distinguish operations engineering from operations research, a branch of industrial engineering. Operations research applies mathematical methods to enhance operational efficiency and cost-effectiveness, determining how to maximize results with limited resources.

Here’s a table highlighting the key differences between Operations Engineering and Operations Research:

Understanding these distinctions is crucial for executives, including COOs, to make informed decisions about the application of these disciplines in specific operational contexts. We’ll discuss this in detail, moving forward.

The Core of Operations Management

The heart of operations management lies in the meticulous planning, organizing, resourcing, directing, and controlling of tasks. The term has evolved over time, from shop management to production-operations management, reflecting the broadening scope of its activities.

Today, operations management encompasses supply chain management, extending from production to product delivery and cash receipt.

Industrial Engineering’s Contribution

Industrial engineering acknowledges F.W. Taylor as the Father of Industrial Engineering, recognizing his critical role in shaping both disciplines. In essence, industrial engineers provide valuable engineering inputs based on customer requirements, cost data, and the working environment, with a keen focus on productivity, quality, and worker comfort.

Product & Process Industrial Engineering

These are the two primary areas within industrial engineering. Product industrial engineering emphasizes improving design and production quality, while process industrial engineering concentrates on enhancing overall productivity and efficiency.

The Synergy Between Industrial Engineering & Operations Management

The amalgamation of industrial engineering into operations management structures highlights the collaborative nature of these disciplines. Industrial engineers, often key participants in cost management activities, contribute significantly to the efficiency improvement and cost reduction of operations.

Addressing Contemporary Challenges

COOs often face a multitude of challenges. Incorporating industrial engineering principles becomes increasingly relevant in addressing these challenges, with a focus on:

Efficient Time Management:

In the pursuit of operational excellence, the application of industrial engineering principles extends beyond conventional methodologies. It serves as a compass for COOs navigating the intricate web of time management. By meticulously streamlining processes, industrial engineering facilitates a culture of efficiency, ensuring that every moment invested contributes meaningfully to organizational goals.

Strategic Skills Enhancement:

The evolution of the workforce is a continual challenge for executives striving for peak performance. Industrial engineering insights provide COOs with a distinctive lens to identify and cultivate essential skills within the workforce.

This strategic approach to skills enhancement ensures that the organization is equipped with the capabilities needed to not only meet current demands but also to adapt proactively to future challenges. It also opens new doors for digital transformation – an essential trope for industries in the coming years.

Visionary Leadership & Precise Execution:

The intersection of visionary leadership and precise execution defines the hallmark of successful operations. COOs, armed with industrial engineering practices, find a synergistic ally in achieving this delicate balance. Industrial engineering fosters a strategic mindset, aligning the visionary goals of leadership with the precision required for flawless execution. It becomes the silent orchestrator of operational harmony.

Holistic Approach to Work-Life Balance:

Acknowledging the critical role of employee well-being, industrial engineering takes a holistic approach to work-life balance. COOs, attuned to the principles of industrial engineering, champion an environment where the comfort and welfare of the workforce are integral components of the operational strategy. This approach not only enhances employee satisfaction but also contributes to sustained productivity and organizational resilience.

Strategic Executive Coaching:

The concept of executive coaching, when viewed through the lens of industrial engineering, transcends traditional mentoring. COOs leveraging industrial engineering principles in executive coaching unlock an array of leadership development and strategic decision-making potential.

This tailored coaching approach aligns with the unique operational challenges faced by executives, nurturing leadership qualities essential for steering the organization through complexities.

Mitigating Security Risks in the Age of AI:

As the embrace of artificial intelligence (AI) becomes a cornerstone of modern operations, COOs must navigate the associated security risks. Industrial engineering emerges as a vital shield in this digital age, providing a systematic approach to identify and address security vulnerabilities. COOs, informed by industrial engineering practices, play a crucial role in ensuring the seamless integration of AI while safeguarding the organization against potential risks.

Crafting Effective Return-to-Office Strategies:

In the post-pandemic landscape, the return to office demands strategic acumen. Industrial engineering insights offer COOs a valuable toolkit for devising effective return-to-office strategies. From optimizing workspace utilization to prioritizing employee well-being, industrial engineering contributes a nuanced perspective that aligns seamlessly with the evolving dynamics of the modern workplace.

In essence, the marriage of industrial engineering principles with the strategic mindset of COOs presents an unparalleled opportunity to navigate operational challenges with finesse. By embracing this holistic approach, COOs not only address current complexities but also fortify their organizations for the unpredictable terrain of the future.

Conclusion

The symbiotic relationship between Industrial Engineering and Operations Management is foundational to the success of modern organizations. COOs and executives navigating the complexities of the industrial landscape can benefit significantly from incorporating industrial engineering principles into their strategic initiatives.

As the business world continues to evolve, the collaboration between these disciplines remains instrumental in achieving operational excellence and sustained growth.

0 Comments